Table of Contents

We always ask customers “target label is woven or printed label machine?”

Why must we ask this questions?

What is the meaning?

Let’s give you more detailed technical information, so that you can understand it.

1. Why we always ask For woven or Printed Label machine?

Many New customers always start with “I want label cut and fold machine. Please tell me price”

While honestly speaking, we have to make clear that your target label is woven or printed? or what is the mostly? Different label types has different characters. The label cutting and folding machine’s working principle can based on label characters.

Following descriptions are based on CHINO MACHINERY YS-3000, YS-4000, YS-5000 seres label cut and fold machines.

1.1 Woven labels

With label and label machine developing, all woven labels can be with woven cut line or pushing line. This line is finished on woven label loom. the actual label section length can be different according to yarn section tension or conditions. We need to make label feeding, cutting according to actual length not nominal. Chino label cutting and folding machine is using this line for actual label length feeding.

1.2 Printed labels

Printed label has no above “cutting or pushing line”. While based on different label printing technology, all label section length can’t be exactly same. Normally individual section length Fluctuate within a certain range, bigger or smaller. Chino Machinery label cutting and folding machine is using developed technology to treat this problems. Electromagnetic pusher + mark tracer can realize accurate cutting and feeding.

2. What is meaning for this questions?

Ok. You understand that we have ask this question now. What is the real meaning of it? Let me give you technical explanation, it will help you to get idea of machine working or the point.

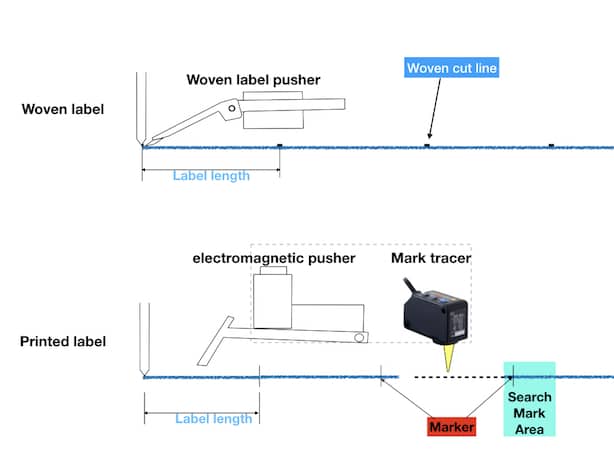

Please refer to following feeding or label length check comparison drawing.

We call above feeding system PUSHER feeding system. It is applied on YS-3000, YS-4000, YS-5000 Chino label cut and fold machines.

Label initial length setting is same for these machines. Mechanical structure is same. For user, we just need to know operation procedure. Please check operation manual for details.

2.1 Woven label feeding system

Ok. We can see that woven label feeding system is with one special pusher, in two sections. First section is with sharp tip to push label pushing line. second section is used to fix.

Please refer to following demo video of pusher moving. It just move left to right, right to left. When we set label length, we just make this moving range a little bigger than max label section length. Anyhow, when pusher will catch the pushing line during feeding movement.

2.2 Printed label feeding system

From above drawing and video demo, we can see that printed label feeding system is some complex. We can’t make machine check label actual length by mechanical method.

Feeding system includes electromagnetic pusher and mark tracer.

Electromagnetic pusher will press label on table to move forward.

Mark tracer is a Optoelectronic method to find actual label length. Optic sensor will scan along label. It will give signal to machine and make pusher start press and push label.

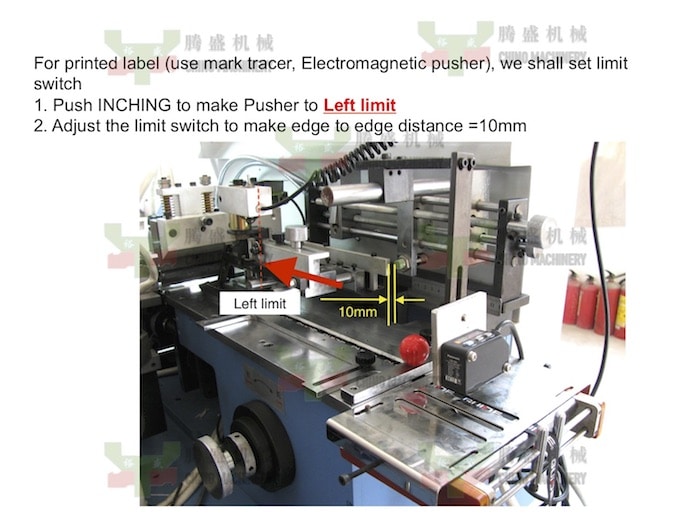

3. Some points for Printed label feeding system

It looks easy to understand but to realize it need many skills. Especially that we are not using CNC control system. Such controller will increase machine cost. We are using traditional mechanical or electric control system.

When a new operator start the machine, he need to catch Skill of Length and Mark Tracer setting for Printed Labels. we need to add some additional during label length setting. Pusher moving range shall be big enough for various label sections.

the reason for above setting is to give mark tracer searching range.

Follow us at YOUTUBE @ Chino Machinery Garment label machines.